Portable Hardness Tester

เครื่องวัดความแข็ง ทดสอบความแข็ง แบบพกพา

เครื่องวัดความแข็ง Portable Hardness Tester – INSPEX

Model

IPX-300 Portable Hardness Tester Integrated Probe

IPX-330+ Portable Hardness Tester External Probe

IPX-340 Portable Hardness Tester External Probe with Built-in Printer

IPX-350 Portable Hardness Tester External Probe wide measuring range, convert hardness

IPX-340 Portable Hardness Tester External Probe wide measuring range, convert hardness with color display

Potable Hardness Tester IPX-330 Plus

High quality, multi functional portable hardness tester from the trusted IPNSPEX range.

Features

- Multi-language and multi-national hardness standards

- Large, color TFT display 320×240

- Measurement range 174-960HL

- High accuracy and repeatability +/-0.5% at 800HL

- conforms to ASTM A 956

- Impact device D included as standard

- Automatic impact device recognition

- Based on HL value, conversion to HRB, HRC, HV, HB, HS and tensile strength

- Up to 10,000 readings on board memory storage

- Auto shut down

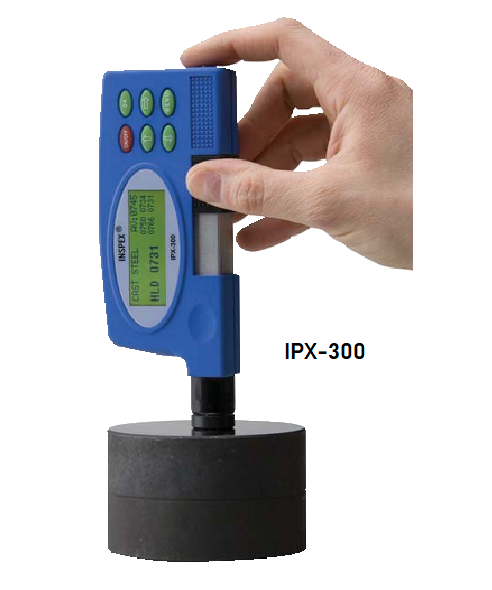

Portable Hardness Tester IPX-300

Handheld dynamic metal hardness tester with hardness conversion and automatic position setting.

Features

• Dynamic hardness testing: quick and reliable

• Impact device D integrated: no cables

• Wide measuring range in HLD and direct display of converted hardness values in Rockwell HRB, HRC, Vickers HV, Brinell HB and Shore HS

• For most metals (see table)

• Provided testing at any angle, even upside down

• Simple handling and low test expenditure

• High accuracy tolerance of maximum 0.5% on solid parts

• Clear LCD display showing all functions and parameters

• USB data output and internal memory batch of 255 average readings

• Conforming to ASTM A 956

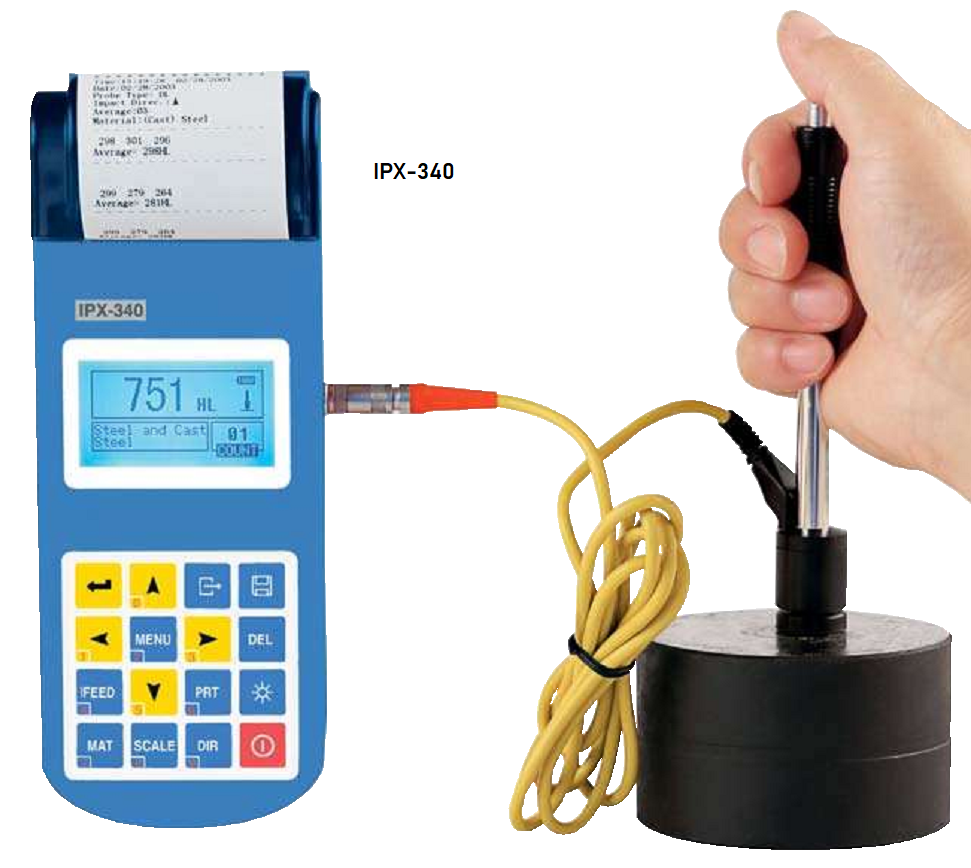

Portable Hardness Tester IPX-340

Portable Hardness Tester with built-in thermal printer

Features

- Advanced Leeb hardness tester with built-in thermal printer

- Large LCD, showing all functions and parameters

- Direct display of hardness scales HRB, HRC, HV, HB, HS, HL

- Automatic recognition of Impact devices

- Upper and lower limit with sound alarm

- Test at any angle, even upside down

- Six impact devices are available for special application

- Battery low indication and sound alarm

- Rechargeable Li battery, intelligent charging

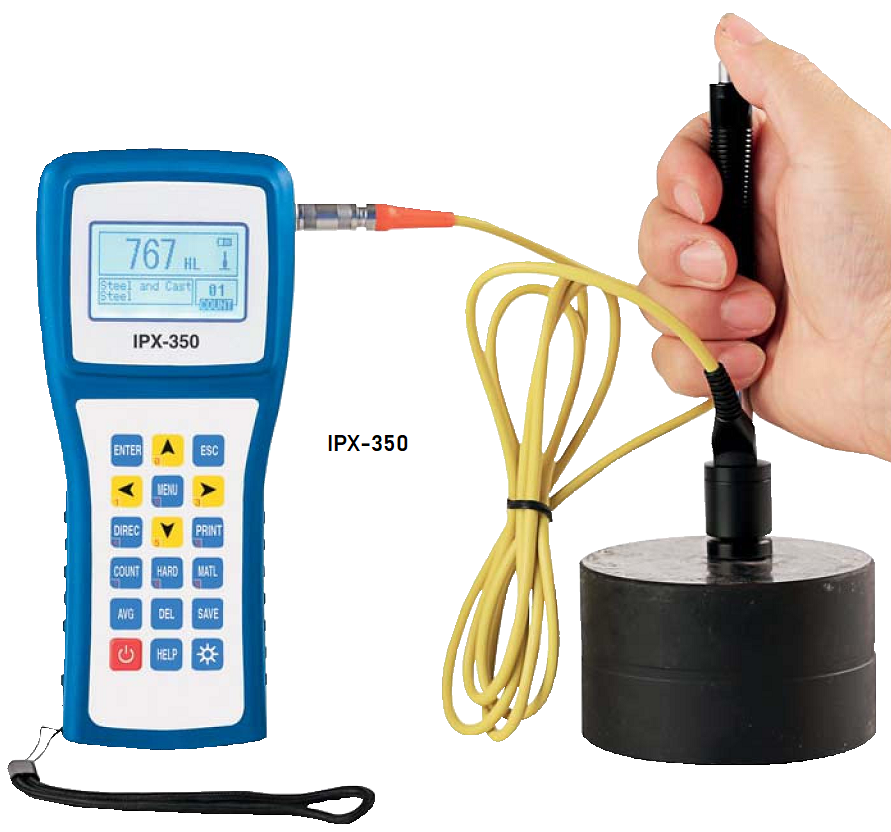

Portable Hardness Tester IPX-350

The IPX-350 portable hardness tester measures a wide measuring range in HL value and directly displays converted hardness in HRC, HRB, HRA, HB, HV and HS.

Features

• Large LED display with backlight display

• Seven impact devices are available for special applications

• Automatically identifies the impact type without re-calibration

• Large memory 48~350 groups (impact average times 32~1)

• Display including single measured value, mean value, testing date, impact direction, impact times, material and hardness scale etc

• Conversion to tensile strength (U.T.S)

• Software calibration function

• Li battery with extra-long working time and standby time

• Dataview software as standard

Portable Hardness Tester IPX-360

Features

• Colour display (320×240 TFT) with adjustable backlight

• �Hardness scales, HRA, HB for D impact device of alloy tool steel;

HV for cast aluminium alloy

• New user material function, user can define own test range.

• Converts to all common hardness scales (HV, HB, HRC, HRB, HRA, HS)

• USB interface

• Seven impact devices are available for special applications

• Max 600 groups (impact times:32~1)

• Upper and lower limit with sound alarm

• Large LED display with backlight display

• Software calibration function

• Rechargeable Li battery with extra-long working time (approx. 200 h)

• Dataview software as standard

เครื่องวัดความแข็ง Combined Hardness Tester NOVOTEST

Model

The device operates both UCI (Ultrasonic Contact Impedance) and the Leeb (dynamic) probes. Getting benefit from two types of measurements is the ultimate advantage that a portable device can provide.

T-UD3

T-UD2

Combined Hardness Tester NOVOTEST T-UD3

- Small indenter imprint (suits for mirror surfaces of shafts necks, blades, gear teeth, etc.)

- Measuring surface hardened layers hardness

- Wide range of hardness testing

- Various measurement modes

- 88 combinations of materials and hardness scales (calibrations)

- Calibration of any scale in any range

- Convenience and ease of measurement

- Optimized number of buttons

- Large full-color graphic display with bright backlight

- Built-in photo camera for thorough reports

- Automatic probe types recognition

- Connected probe types indication

- The calibrations are stored in UCI probe memory

- Extended operating temperature range (frost, down to – 40°C)

- Internal memory and communication with a PC

- New intuitive menu with tips on the buttons

- Optional wireless mini printer

- Waterproofed housing

- Rubber bumper protected housing

- Internal clock

- Hardness value measuring for any mass products with more than 1 mm thickness (small parts, thin-walled structures, pipes, tanks, steel sheets, articles of complex shape, hardness testing of metal coatings, etc.)

- Different operating modes:

- Graph – the graph building mode

- Histogram – the histogram building mode

- Statistics – provides statistics for the current set of measurements

- Smart – filters the incorrect measurements

- Signal – displays the probe signal (only for the Leeb probe)

Combined Hardness Tester NOVOTEST T-UD2

Combined Hardness Tester NOVOTEST T-UD2 is designed for rapid non-destructive hardness testing of :

- metals and alloys on standardized hardness scales;

- metals with different properties from steel (for example, non-ferrous metals, alloys, cast iron, etc.) with additional scales for calibration;

- use the scale of tensile strength (Rm) for determining the tensile strength of carbon steel products pearlitic by automatically converting from Brinell (HB) hardness scale.

Device implements 2 methods of testing: rebound (Leeb) and ultrasonic contact impedance (UCI). The combination of both methods allows user to test all range of metal products.

Advantage

Wireless Hardness Tester NOVOTEST Lab UCI

The NOVOTEST Lab UCI wireless hardness tester implements the ultrasonic contact impedance method.

The users of NOVOTEST Lab UCI get the following advantages:

- Ultra-portable device for quick hardness testing anywhere – in laboratories or in field conditions, with autonomous continuous operation up to 20 hours.

- UCI hardness test method has almost no boundaries in relation to the test object, so this method is the most versatile of the existing ones.

- Multifunctional application “NOVOTEST Lab” with a user-friendly interface and cloud archive.

Powerful functionality

Powerful functionality

The NOVOTEST Lab app allows users to:

– set up and calibrate the device;

– to get illustrations of measurements as graphs, histograms, and statistics;

– save measurements with text-, audio-, photo- and even videos protocols;

– transfer the protocol in one click by any convenient messenger or e-mail;

– synchronize archive with cloud storage.

And much more!

Specifications

Measurement hardness range:

|

|

| Scales | HRC, HB, HV, HRA, HRB, MPA and can be calibrated for any other scales |

| Materials | Steel, aluminum, brass and can be calibrated for any other materials |

| Measurement accuracy |

|

| Measuring direction | Any direction 360° |

| Standards |

|

| Wireless connection with Android gadgets via NOVOTEST Lab App | Yes |

| Weight, g | 170 |

| Dimensions, mm | 160*26 (36 with nozzle) |

| Battery life, h | 10 |

| Power supply / Charging | Built-in battery / USB 5V |

| Operating environment | Temperature:-30°C~60°CHumidity: 30%~80%R.H. |

| Package gross weight, kg | 1.5 |

Standard Package

- Hardness tester

- Special nozzle

- Software

- USB cable

- Operating manual

- Case

* Smartphone is not included in the standard set.

UCI Hardness Tester NOVOTEST

Model

The Ultrasonic Contact Impedance (UCI) probe is used for measuring the hardness value of small items, objects with a thin wall, complex form, and to measure the hardness of surface hardened layers.

Built-in camera allows user to picture of testing object and mark tested area with corresponding hardness value.

UCI Hardness Tester NOVOTEST T-U3 has the sealed housing with rubber protective strips, it is ideal for use in workshop, and field conditions with high humidity, dust, etc. The hardness tester has frost-resistant display, which allows user to use the device at any season and in any climatic zone of the Earth.

The device has PC software with a comfortable and intuitive interface.

- T-U3

- T-U2

UCI Hardness Tester NOVOTEST T-U3

- Hardness measurement of any mass products with a thickness more than 1 mm – inaccessible to the dynamic (Leeb) hardness testers (small parts, thin-walled structures, pipes, tanks, steel sheets, articles of complex shape, hardness control of metal coatings, etc.)

- Measuring the hardness of the surface hardened layer

- Small imprint after measuring (mirror surfaces of shafts necks, blades, gear teeth, etc.)

- Wide range of hardness testing

- Various measurement modes

- Calibration of any scale in any range

- Convenience and ease for measurement

- Optimized number of buttons

- Large full color graphic display with bright back-lighting

- Calibrations stored in memory of probe

- Extended temperature range (frost, down to – 40°C)

- Internal memory and communication with PC

- New, intuitive menu with tips on the buttons

- Optional wireless mini printer

- Water resistant case

- Rubber protected bumper

- Has different operating modes:

Graph – the mode of building of graph

Histogram – the mode of building of histogram

Statistics – the mode of statistic

Smart – the mode of filtering of incorrect measurements

UCI hardness tester NOVOTEST T-U2

UCI hardness tester NOVOTEST T-U2 is designed for rapid non-destructive hardness testing of:

- metals and alloys on standardized international scales of hardness: Rockwell (HRC), Brinell (HB), Vickers (HV);

- metals with distinctions in properties of steel (e.g., non-ferrous metals, alloys of iron and others.) and using five additional scales for calibration;

- using a scale of tensile strength (Rm) to determine the tensile strength of carbon steel pearlitic products by automatic recalculation from Brinell (HB) hardness scale

Ultrasonic hardness tester T-U2 implements the ultrasonic contact impedance method (UCI).

- Possibility of measuring the hardness value of products with any weights and thickness from 1 mm (small items, thin-walled structures, pipes, tanks, steel sheets, the products of complex shape, hardness control of metal coatings, etc.)

- Small mark on the surface of the tested product (user can test mirror surfaces, necks shafts, knives, gear teeth, etc.)

- Hardness testing the hardening layer of the surface

- Wide range of hardness measuring

- Usability of measuring

- Minimum number of controls

- Big graphic display with brightness backlighting

- Control the charge level of batteries

- Extended temperature range (frost protected, operating temperature up to -20 °C)

- Device has internal memory and allows user to connect with PC

- New, intuitive menu with tips on the buttons

ULTRASONIC Portable Tester MET-U1A

Model

| W-MET-U1A | Ultrasonic Portable Hardness Tester |

| W-MET-U1A/10 | Stand for MET-U1A probe |

Ultrasonic Portable Hardness Tester MET-U1A

Portable hardness tester for accurate testing on metals, plastics and ceramics.

Features

• Uses UCI principle of hardness testing

• Suitable for hardness testing of metals, plastics and ceramics

• Rockwell (HRC), Brinell (HB), Vickers (HV) and Shore (HSD)

• Leaves almost no visible indent on the tested article surface

Ultrasonic Portable Hardness Tester “Ultramatic”

Features

- Ultrasonic Contact Impedance test principle: very accurate!

- Suitable for hardness tests on metals, plastics, ceramics

- Direct reading in Vickers HV, and direct conversion to HRC, HRB, HB and UTS

- High reproducibility within ±1%

- Extensive range of application at locations difficult to access

- Large memory, statistics and data output

- Windows software for testing, data processing and documentation

WEBSTER Portable Hardness Tester

Model

| Code No. | Material | Thickness | Diameter (mm) |

|---|---|---|---|

| CV-WH100 | Aluminium alloy | Max. 6 | Min. 10 |

| CV-WH110 | Aluminium alloy | Max. 13 | Min. 10 |

| CV-WH120 | Aluminium alloy | Max. 8 | Min. 6 |

| CV-WH130 | Brass in hard/half hard state super-hard Aluminium alloy | Max. 6 | Min. 10 |

| CV-WH140 | Brass in hard/half hard state super-hard Aluminium alloy | Max. 8 | Min. 6 |

| CV-WH150 | Soft Brass, pure Copper | Max. 6 | Min. 10 |

| CV-WH160 | Soft Brass, pure Copper | Max. 8 | Min. 6 |

| CV-WH170 | Cold-rolled steel sheet, stainless steel | Max. 8 | Min. 6 |

Webster Type Portable Hardness Tester

The WEBSTER Hardness Testers are portable instruments that can perform on-site hardness testing on aluminium alloys, brass, copper and soft steel. A quick and easy test, the hardness value can be read out directly from the indicator with a simple clamp. Suitable for testing aluminium alloy profiles, tubings and sheet materials. Especially suitable for fast, non destructive quality inspection on the production site.

Features

• One hand operation and portability

• Variety of anvils permits testing a great variance of shapes

• Simple operation permits readings independent of the operator’s skill

• Test is made by simply applying pressure to the handles until “bottom” is felt

• Easy-to-read dial indicator with 20 graduations permits use of the tester as “go” and “no-go” gauge

• Standard hardness gauge tests materials up to 13mm in thickness

| Measuring Scope | 0-20HW |

| Accuracy | 0.5HW |

| Net Weight | 0.5kg |

| Package Gross Weight | 1.55kg |

| Package Dimensions | 330mm x 255mm x 150mm |

Construction Materials Testing

Model

Strength Meter NOVOTEST IPSM-U+T+D (Pulse Velocity Tester)

Strength Meter NOVOTEST IPSM-U+T+D (Pulse Velocity Tester)

The pulse velocity tester IPSM-U+T+D allows to measure the strength and homogeneity of the concrete, bricks and other materials under the composition and surface sounding in products and designs for construction projects, inspection of buildings and structures, according to ASTM C597-16 (Standard Test Method for Pulse Velocity Through Concrete). Has the determining of the depth of cracks by the surface sounding probe function and also flaw detection mode (A-scan).

Measuring the strength and uniformity of construction materials by ultrasonic method NOVOTEST IPSM-U+T+D is designed for :

- detection of voids, cracks and defects encountered in the production and operation of structures (for process control and inspection of facilities);

- control and uniformity of concrete strength (Guidelines MDS 62-2.01), construction and composite materials, structures, bridges and waterworks;

- measure the depth of cracks in the tested materials;

- determine the density and elastic modulus fiberglass and so on;

- definitions of sound index of construction ceramics and abrasives;

- estimates of the porosity, fracturing and anisotropy of the material;

- assess the degree of maturity of the concrete in a monolithic concreting;

- visualize the presence of a signal (A-scan);

- the possibility of test the concrete (and other) constructions for internal defects, discontinuities;

- improve the accuracy of measurement of time intervals by allowing manual selection of the moment trip meter.

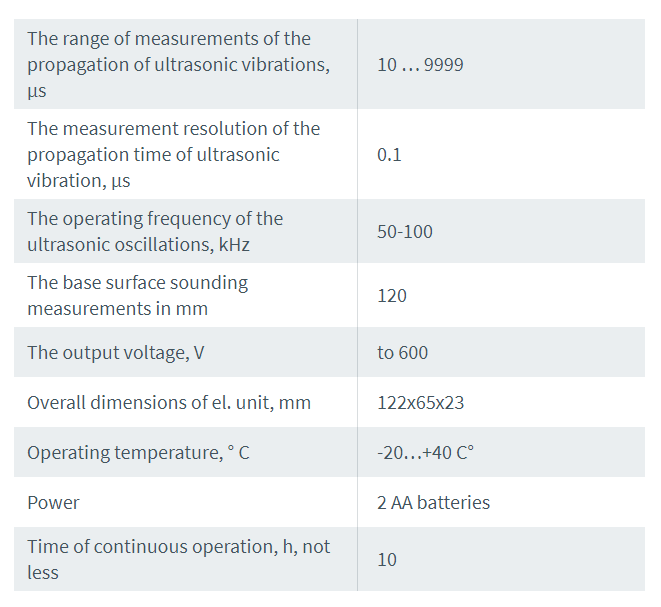

Specification

Portable Hardness Tester – INSTRUMATIC

Model

| Code No. | Description | Scale |

|---|---|---|

| POR0006 | No. 6 | Brinell 40-300mm/Vickers Pyramid 40-300mm |

| POR0003 | No. 3 | Vickers Pyramid 100-1000mm/Brinell 100-400mm/Rockwell B 50-99mm/Rockwell C 20-70mm |

| POR0002 | No. 2 | Rockwell A 40-85mm/Rockwell B 50-100mm/Rockwell C 20-70mm |

| PBS0001 | Precision Bench Stand |

Features

CV Portable Analogue Hardness Testers – CV Instrumatic

A fully mechanical instrument of the highest precision, robust, and maintenance free. The large clearly marked dials on these unique instruments cover a full range of hardness values in Vickers, Brinell, Rockwell A, B, C, covering national and international standards. The Instrument The system is entirely mechanical employing the use of special pre-loaded springs which provide a load of about 15Kg to the diamond. Maximum penetration of the diamond into the specimen is 0.125mm (0.005″). Operation and Use The simplicity of the tester enables it to be used in almost any direction, without affecting accuracy. It can be used ‘on site’ with complete success. The grips are depressed to the fullest extent by using the palms of the hands and the hardness value can be read off the appropriate scale. Repeatability is excellent and the calibration can be checked by the user against a UKAS certified reference test block supplied with each instrument. Each tester is supplied complete with case and detailed operating instructions.

Features • Accurate and easy to use • No batteries required • UKAS certified test block supplied • Optional bench stand with V base for round parts • Precision Instrument • Able to test even thin materials due to low penetration of indenter (0.25mm and above) • Bench stand available for testing small components • No. 3 – general purpose

| Desc. | Scale | Range (mm) | Scale | Range (mm) | Scale | Range (mm) | Scale | Range (mm) | |||

| No. 2 | Rockwell A | 40-85 | Vickers Pyramid | 50-100 | Brinell | 20-70 | |||||

| No. 3 | Vickers Pyramid | 100-1000 | Brinell | 100-400 | Rockwell B | 50-99 | Rockwell C | 20-70 | |||

| No. 6 | Brinell | 40-300 | Vickers Pyramid | 40-300 |

Portable Hardness Tester – Rangemaster

Model

| Code No. | Description | Length 1 | Output | Functions | PC Connectivity |

|---|---|---|---|---|---|

| RAN0004 | RS232 PC Connection Cable | 2 | Rangemaster to PC | Data Send Only | 9 Pin Female |

| RANP001 | Rangemaster with UKAS certified test blocks | ||||

| RANP002 | Rangemaster with factory certified test blocks |

Features

CV Portable Digital Hardness Tester

The Bowers CV Rangemaster Plus Hardness Tester represents an ideal solution to the problems associated with portable hardness testing. Its clear digital display, ease of use and ability to operate in all major international scales make it the most comprehensive unit of its type currently available.

Features

• Dynamic test indicator

• Large digital readout

• Hardness values in all major international scales with simple conversion facilities from one to the other

• RS232 output for connection to PC or serial printer

• Memory storage range for in excess of 400 readings

• Statistical summary

• Integral icon facility provides operator with easy visual identification of mode in which unit is operating

• Operates in temperatures from -5ºC to +35ºC

• Upper and lower control limits

• Last reading recall

• Supplied with a UKAS certified test block, adjuster key and carrying case

| Hardness Scale | Vickers Pyramid No. – Brinell – Rockwell B – Rockwell C – Tensile Strength – Shore Scleroscope |

| Testing Range | Vickers Pyramid No. – 35-1000 – Brinell – 100-500 – Rockwell B – 30-100 – Rockwell C – 20-70 – Tensile Strength – 255-1999 N/mm≈ – Shore Scleroscope – 24-97 |

| Resolution | 1 Vickers Pyramid No. – Brinell – Tensile Strength – Shore Scleroscope – 0.1 – Rockwell B – Rockwell |

| Power | 9V battery or adaptor |

| Output | RS-232 serial output |

Magnetic Rockwell

Model

CV-MR01 Magnetic Rockwell

CV-MRD01 Magnetic Rockwell Digital Display

Features

Magnetic Rockwell CV-MR01

Magnetic base hardness tester designed according to the principle of Rockwell hardness testing.

Features

• Magnetic base hardness tester designed according to the principle of Rockwell hardness testing

• The test head can be fixed to the surface of iron and steel components by magnetic force

• Support to the test piece is not required as the 350kg+ magnetic base will hold the unit firmly in position

• The testing accuracy complies to ISO6508 or ASTM E18 and is comparable to a Rockwell bench hardness tester

• Testing can be done regardless of the shape of the component as long as there is a flat surface for positioning of the magnetic base

• Able to test large-size workpieces which are assembled, unable to cut or inconvenient to move such as the large-size moulds, steel plate, steel tube, steel structure, boiler, pressure vessel, metallic pipe lines or the slide ways of machine tools

Shore Scale Durometer

Model

| SHA0001 | Analogue Shore ‘A’ Scale |

| SHD0002 | Analogue Shore ‘D’ Scale |

| DSAS001 | Digital ‘A’ Scale Durometer, Sylvac RS232 output |

| DSDS001 | Digital ‘D’ Scale Durometer, Sylvac RS232 output |

| SHA0003 | Shore ‘A/D’ Bench Stand |

Features

CV Shore Durometers – Analogue / Digital

These advanced Shore Scale Durometers provide fast easy-to-read instruments ideal for testing rubber, plastic, leather and all other soft materials. The gauges can be used in hand held mode or mounted onto a sturdy bench stand for improved accuracy and repeatability.

Features: Analogue

• Fast and easy to read

• Portable

• Hand-held operation or via optional bench stand

• Available in either Shore A or Shore D

• Supplied with a setting / reference block

• Supplied with UKAS calibration certificate