Measuring Instruments

Hand Tools เครื่องมือช่าง

Traditional Engineers’ Square 400 series

Features

• Precision ground blade and stock

• Blind rivetted construction

• Hardened and tempered blades

• 3″ & 4″ available in Retail Packs

Model

| Code No. | Blade Length (mm) | Blade Length (inch) | Stock Length (mm) |

|---|---|---|---|

| 4003 | 75 | 3 | 49 |

| 4004 | 100 | 4 | 56 |

| 4006 | 150 | 6 | 82 |

| 4009 | 225 | 9 | 108 |

| 40012 | 300 | 12 | 139 |

Precision Engineers’ Square

Features

• Manufactured according to DIN 875

• Made of hardened stainless steel

• Precision ground and micro-lapped

• 2 knife-form sides with angle of 40°

Model

| Code No. | Description |

|---|---|

| MW910-01 | 40 x 30mm |

| MW910-02 | 50 x 40mm |

| MW910-03 | 75 x 50mm |

| MW910-04 | 100 x 70mm |

| MW910-05 | 150 x 100mm |

| MW910-06 | 200 x 130mm |

Engineers’ Rule MW900

Features

Standard: DIN 874 Grade 00

• Made of hardened alloy steel

• Precision ground and micro-lapped

• Knife-form with angle of 30º

• Packed individually in leather-look bag

Model

|

Code No.

|

Length (mm) |

| MW900-01 | 50 |

| MW900-02 | 75 |

| MW900-03 | 100 |

| MW900-04 | 125 |

| MW900-05 | 150 |

| MW900-06 | 200 |

| MW900-07 | 300 |

| MW900-08 | 400 |

Feeler Gauge

Precision Range:

Complies with DIN 2275

- All blades are hardened, tempered and polished

- Nominal thickness marked on each blade

- Replacement blades available

- 3″/75 mm and 4″/100 mm available in retail pack

Safe and Sure Range:

- An economical range of feeler sets for general workshop use

- All blades are hardened, tempered and polished

- Nominal thickness marked on each blade

Model

Metric Precision Range

| Code No. | Length (mm) | Locking Screw | No. of Blades | Pack Quantity |

|---|---|---|---|---|

| 387M | 75 | Yes | 13 | 1 |

| 388M | 100 | Yes | 13 | 1 |

| 389M | 100 | No | 13 | 1 |

| 394M | 150 | No | 13 | 1 |

| 398M | 300 | Yes | 13 | 1 |

| 391M | 75 | No | 11 | 1 |

| 393M | 75 | No | 20 | 1 |

| 390M | 100 | No | 20 | 1 |

| 395M | 150 | No | 20 | 1 |

| 399M | 300 | Yes | 20 | 1 |

Safe and Sure Range

| Code No. | Length (mm) | Locking Screw | No. of Blades | Pack Quantity |

|---|---|---|---|---|

| 912M | 75 | No | 10 | 1 |

| 911M | 100 | No | 10 | 1 |

| 1106M | 150 | No | 10 | 1 |

| 1112M | 300 | No | 10 | 1 |

Feeler Strip

Model Feeler Strip Set

Feeler Strip Set

| Code No. | Range |

|---|---|

| FS20M | Metric 20 Piece Feeler Strip Set |

| FS20E | Imperial 20 Piece Feeler Strip Set |

Model Feeler Strip

Feeler Strip

| Code No. | Length (mm) | Pack Quantity |

|---|---|---|

| 126M003 | 300 | 10 |

| 126M004 | 300 | 10 |

| 126M005 | 300 | 10 |

| 126M006 | 300 | 10 |

| 126M007 | 300 | 10 |

| 126M008 | 300 | 10 |

| 126M009 | 300 | 10 |

| 126M010 | 300 | 10 |

| 126M015 | 300 | 10 |

| 126M020 | 300 | 10 |

| 126M025 | 300 | 10 |

| 126M030 | 300 | 10 |

| 126M035 | 300 | 10 |

| 126M040 | 300 | 10 |

| 126M045 | 300 | 10 |

| 126M050 | 300 | 10 |

| 126M055 | 300 | 10 |

| 126M060 | 300 | 10 |

Features

Feeler Strip Sets

Complies with DIN 2275

• 20 piece feeler strip in wallet

• Hardened, tempered and polished steel strip

• Nominal thickness is marked on each strip

• Imperial Set: Length 6″, Range 1-25 Thou

• Metric Set: Length 150mm, Range 0.03 to 1.00mm

Feeler Strip 126M Series

Complies with DIN 2275

• Hardened, tempered and polished steel strip

• Nominal thickness is marked on each strip

• Pack quantity 10

Traditional (Hermaphrodite) Calipers

Model

| Code No. | Description | Size | Pack Quantity |

|---|---|---|---|

| 341 | Firm Joint | 125mm / 5″ | 5 |

| 336-6 | Firm Joint | 150mm /6″ | 5 |

| 56 | Spring Joint | 150mm / 6″ | 5 |

Features

Firm Joint Adjustable Point:

• Manufactured from polished tool steel

• A large headed nut and screw assembly provides a firm and rigid friction joint, with no play

• The sizes listed are the effective leg length which is measured from the joint assembly

• Leg which holds the round adjustable hardened point is offset

• Model 341 has a locating spur on the straight leg

Note: Firm joint caliper capacities are generally 1/3 greater than the effective leg length.

Spring Joint:

• Manufactured from polished tool steel

• The marking leg is hardened to over 550Hv at the point

• Bow spring ensures uniform tension over working range

• Centrally mounted adjustment screw offers finer setting than firm joint type

Traditional Inside & Outside Calipers

Features

Standard : BS3123

Firm Joint

- Manufactured from polished tool steel

- A large headed nut & screw assembly provides a firm & rigid friction joint, with no play

- The sizes listed are the effective leg length which is measured from the joint assembly

Spring Joint

Outside Caliper, Spring Joint:

- Bow spring ensures uniform tension over working range

- Centrally mounted adjustment screw offers finer setting than firm joint type

Inside Calipers, Spring Joint:

- Bow spring ensures uniform tension over working range

- Centrally mounted adjustment screw

- Manufactured from polished tool steel

Spring Dividers

Spring Dividers:

- Manufactured from polished tool steel

- Points are hardened to over 550Hv

- Bow spring ensures uniform tension over working range

- Centrally mounted adjustment screw

Powder Coated Calipers & Dividers

Features

• Powder coated steel for extra durability

• Sizes listed are the effective leg length which is measured from the joint assembly

Model

| Code No. | Description | Size |

|---|---|---|

| MW504P | Dividers | 100mm / 4″ |

| MW506P | Dividers | 150mm / 6″ |

| MW5012P | Dividers | 300mm / 12″ |

| MW514P | Inside Calipers | 100mm / 4″ |

| MW516P | Inside Calipers | 150mm / 6″ |

| MW5112P | Inside Calipers | 300mm / 12″ |

| MW524P | Outside Calipers | 100mm / 4″ |

| MW526P | Outside Calipers | 150mm / 6″ |

| MW5212P | Outside Calipers | 300mm / 12″ |

Digital Inside / Outside Caliper

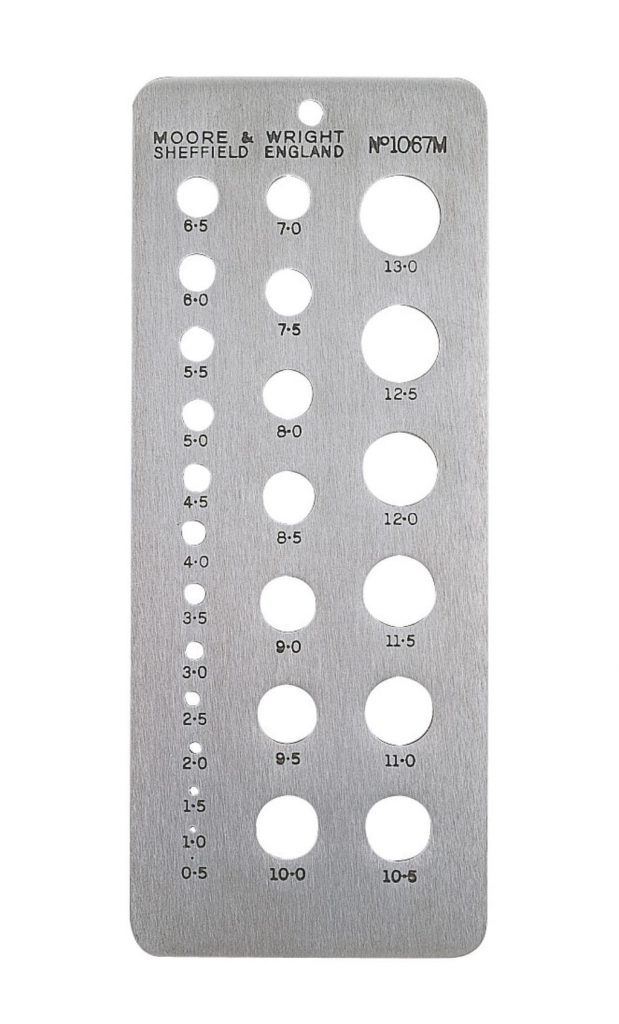

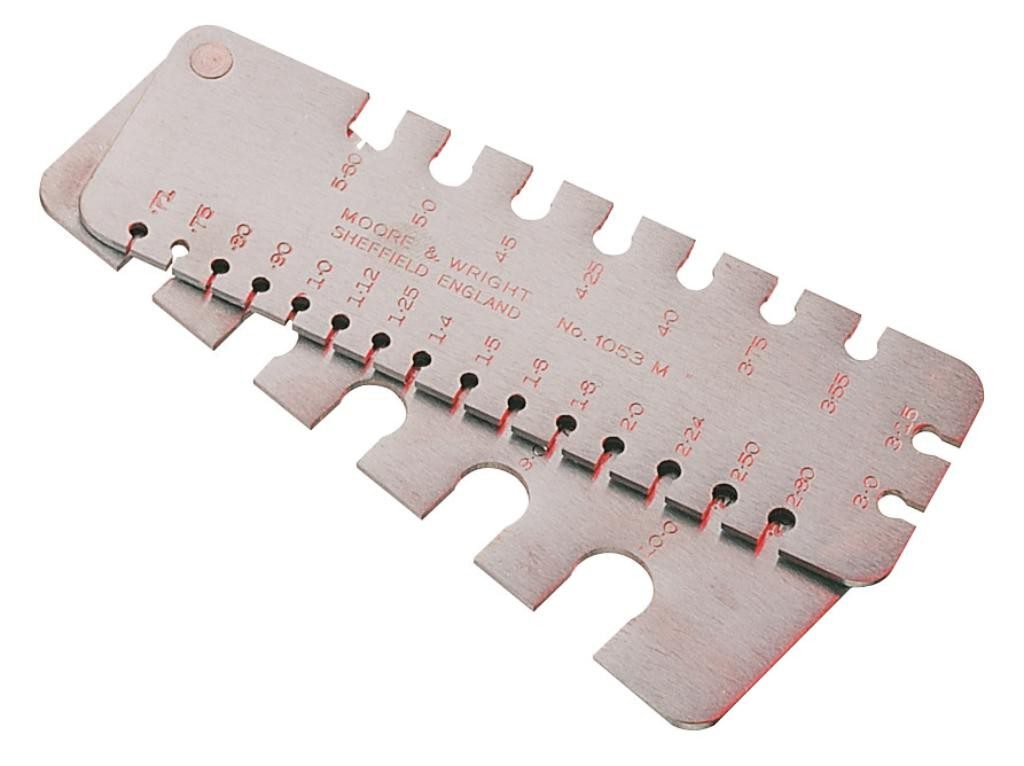

Traditional Drill Gauge

Standard Wire Gauge

Features

• Two part space saving design, with corner pivot

• Marked with nominal size of each slot

• Made from high grade tool steel, with a brushed finish

• 1067M & 1053M available in Retail Packs

Model

| Code No. | No. of Slots | Range of Slot Size | Graduation (mm) |

|---|---|---|---|

| 153M | 40 | 0.2-10.0mm | |

| 1052 | 36 | 1-36 SWG | |

Traditional Surface Gauge

Features

Universal type:

• Designed for precise marking out operations

• Hardened and tempered steel base, ground on one end and bottom face

• Vee groove for locating on cylindrical workpieces

• Two retractable locating pins

• Radial grooves in the side facilitate comfortable handling

• One handed fine adjustment

• Supplied with two interchangeable pillars and one 4mm diameter scriber

Note: Surface gauges can be used for mounting dial test indicators with either a 4mm or 6.35mm (1/4″) mounting spigot.

Model

| Code No. | Description | Height (mm) | Height (inch) | Size of Base |

|---|---|---|---|---|

| E101B | Universal | 225 & 300 | 9 & 12 | 80 x 65mm, 3 1/8 x 2 1/2″ |

| E102B | Universal | 300 & 450 | 12 & 18 | 105 x 85mm, 4 1/8 x 3 3/8″ |

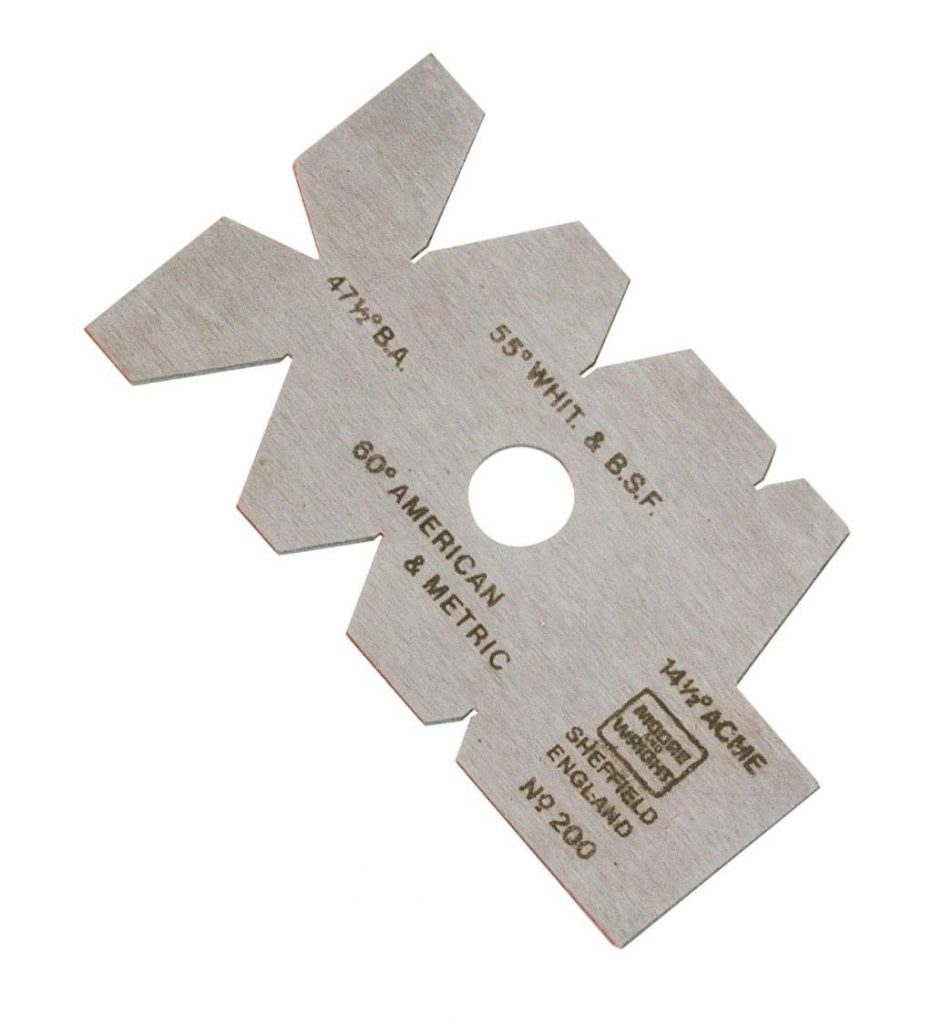

Traditional Screw Cutting Gauges

Features

• Traditional Engineers’ screw cutting gauge

• Suitable for most standard metric and imperial thread forms

• Accurately milled angles for precise evaluation of thread form

• Available in Retail Packs

Model

| Code No | Angle | Thread Form |

| MW200 | 60° | SI, ISO, US Std. |

| 55° | Whitworth | |

| 47.5° | British Assosiation (BA) | |

| 14.5° | ACME |

Traditional Radius Gauges

Features

• Accurately milled steel blades

• Designed to check both internal and external radii

• Marked with nominal size on each blade

• Mounted either on a ring or in a steel sleeve

Model

METRIC: Radius Gauges,0.75 – 13mm

| Code No. | Description | Range (mm) | No. of Blades | Graduation (mm) |

|---|---|---|---|---|

| 204M | Ring | 0.75-5 | 18 | 0.25 |

| 206M | Sleeve | 0.75-5 | 18 | 0.25 |

| 204MA | Ring | 5.5-13 | 16 | 0.5 |

| 206MA | Sleeve | 5.5-13 | 16 | 0.5 |

IMPERIAL: Radius Gauges, 1/32 – 33/64

| Code No. | Description | Range (mm) | No. of Blades | Graduation (mm) |

|---|---|---|---|---|

| 204 | Ring | 1/32-17/64 | 16 | 1/64 |

| 206 | Sleeve | 1/32-17/64 | 16 | 1/64 |

| 204A | Ring | 9/32-33/64 | 16 | 1/64 |

| 206A | Sleeve | 9/32-33-64 | 16 | 1/64 |

Back to Measuring Instruments | Vernier Caliper | Micrometer | Height Gauge | Depth Gauge | Tyre Profile Gauge | Cylinder Bore Gauge | Dial Indicator and Stand | Thickness Gauge | Combination Set | Protractor| Level| Gauge Block|Engineer Square|Setting Master Gauge|Surface Plate|Angle Meter|Feeler Gauge|Caliper|Traditional Drill Gauge, Wire Gauge|Screw Cutting Gauge|Radius Gauge| Screw Pitch Gauge|Steel Pin Gauge Set|Carbide Tipped Scriber

เหตุผลดีๆ ที่ต้องเลือกซื้อสินค้าจากเรา

- FAST DELIVERY บริการจัดส่งรวดเร็ว

เราให้ความสำคัญในการจัดส่งสินค้าที่รวดเร็ว ตรวจเช็คคุณภาพสินค้าก่อนส่งทุกครั้ง

2. Guarantee รับประกันคุณภาพ

สินค้าทุกชิ้นมีการรับประกัน 1 ปี (ตามเงื่อนไขที่กำหนด)

3. Free Consult บริการตอบคำถามลูกค้า

เรามีพนักงานขาย คอยดูแล ตอบคำถามทุกข้อสงสัยเกี่ยวกับสินค้าได้เป็นอย่างดี และมีบริการสาธิตการใช้งาน ฟรี

4. AFTER SALE SERVICE บริการดูแลหลังการขาย

สินค้ามีปัญหาไม่ต้องกังวล แจ้งเคลมสินค้า ติดต่อพนักงานดูแลหลังการขายได้ทันที หรือ โทร 0-2565-9370-4

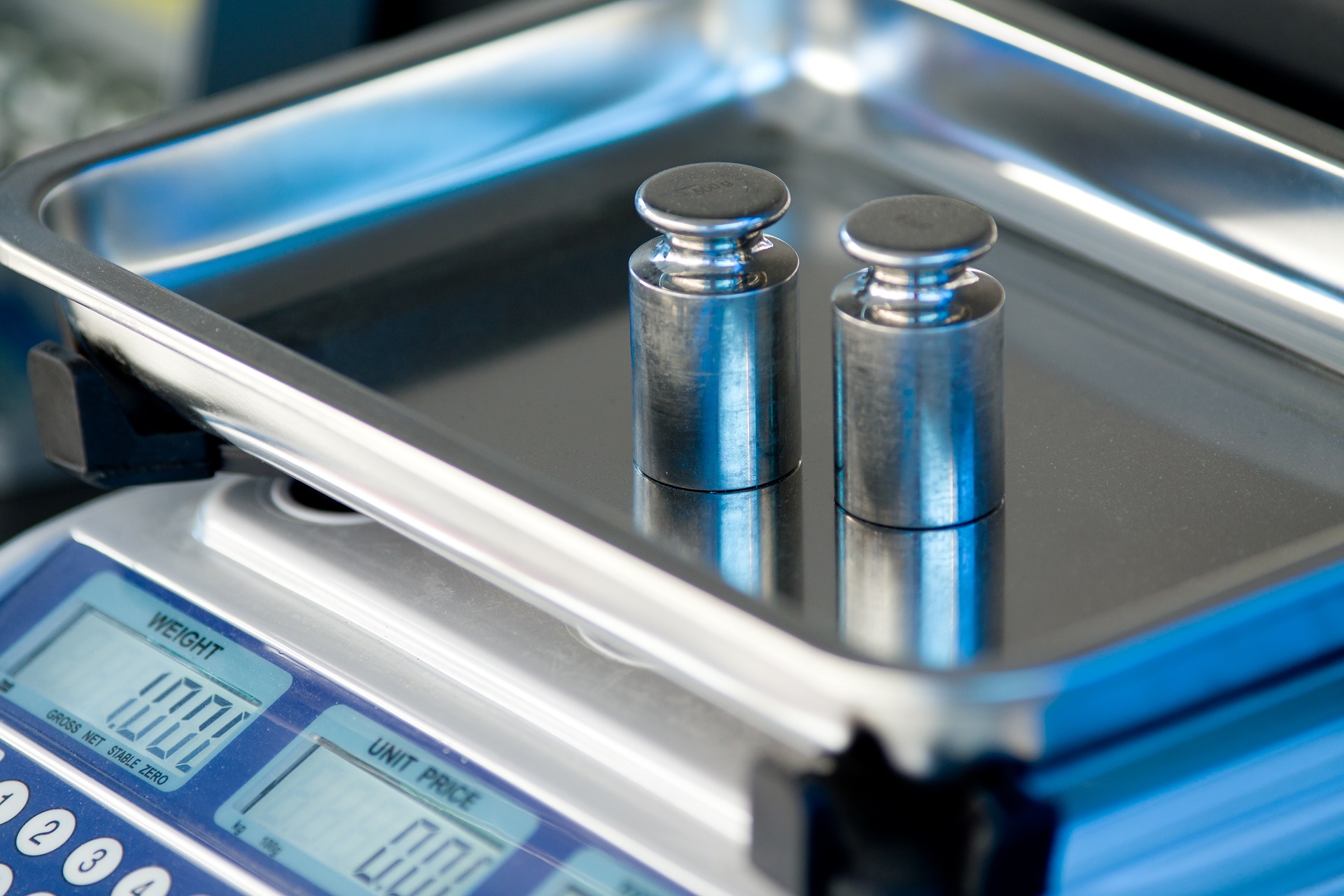

5. Calibration Service บริการสอบเทียบ

เรามีบริการสอบเทียบเครื่องมือวัด ด้วย LAB มาตรฐาน ISO-17025

6. Seminar and Training การจัดสัมมนาและฝึกอบรม

เราสามารถจัดฝึกอบรมและสัมมนาให้ความรู้ ทั้งในและนอกสถานที่